Our Products

SOFTWOODS

These woods are usually lighter and less dense than hardwoods and are commonly used in construction, carpentry, and woodworking. Some examples of softwood species include Pine, Spruce, Fir. They are often chosen for their easy workability, affordability, and suitability for outdoor applications due to their natural resistance to decay and insects.

Origins

New zealand | Brazil | Lithuania | Russia Ukraine | Austria

1” x 4” x 3 & 4 Mtr, 1” x 6” x 4 Mtr, 2” x 4” x 4 Mtr, 3” x 3” x 4 & 3 Mtr, 4” x 4” x 4 & 3 Mtr, 6” x 6” x 4 Mtr

Pallets are commonly used in industries such as logistics, warehousing, and shipping. Pallet wood is typically inexpensive because it's often made from lower-grade or reclaimed wood. However, it can be repurposed for various DIY projects such as furniture making, home decor, and even outdoor structures like raised garden beds or decks.

Origins

New zealand | Brazil | Lithuania | Russia Ukraine | Austria

PALLET WOODS

HARDWOODS

Hard woods are known for their dense and durable characteristics, making them suitable for a wide range of applications, including furniture making, flooring, cabinetry, musical instruments, and more. Hardwoods are prized for their strength, stability, and attractive grain patterns, which often make them preferred choices for high-quality furniture and woodworking projects.

Due to their density and durability, hardwoods typically have a higher cost compared to softwoods, which come from coniferous trees. However, the investment in hardwoods often pays off in terms of longevity and aesthetics.

MDF stands for Medium Density Fiberboard. It's a type of engineered wood product made by breaking down hardwood or softwood residuals into wood fibers and combining them with wax and a resin binder under high temperature and pressure. MDF is commonly used in furniture making, cabinetry, shelving, and molding, among other applications.

Different Origins

Available in all sizes

4mm, 6mm, 9mm, 12mm, 15mm, 18mm

MDF

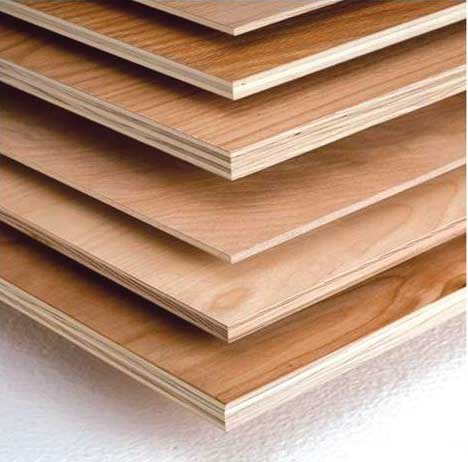

Plywoods

Plywood is commonly used in construction, furniture making, cabinetry, flooring, and various other applications

Origins

Indonesia, China, Malaysia, India

Ordinary Plywood

Available in all sizes

4mm, 6mm, 9mm, 12mm, 15mm, 18mm

Shuttering / Film Faced Plywood

Available in all sizes

15mm, 18mm

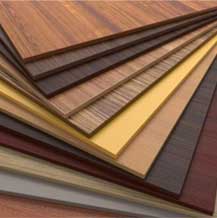

MELAMINE FACED CHIPBOARD (MFC) is an essential material component used in the furniture and interior design industries. It is made from particle board covered with decorative paper pigmented with melamine resin. Our Melamine faced chipboard is available in various sizes, thicknesses and finishes including glossy, matt, wood grain and patterns. Alujain represents the highest European brands in this sector and offers Melamine faced MDF as well. Matching edge bends are available for all colors

MFC

PLYWOOD VENEERS

Plywood veneers refer to the thin slices or sheets of wood that are used to create the face and back layers of plywood panels. These veneers are typically obtained by peeling or slicing logs into thin layers, although rotary cutting is the most common method.

The quality of the veneers used in plywood can greatly influence the overall quality and appearance of the finished product. High-quality veneers with consistent grain patterns and minimal defects can result in a smooth, uniform, and aesthetically pleasing surface finish. Cross-graining technique enhances the strength, stability, and resistance to warping of the plywood panel.

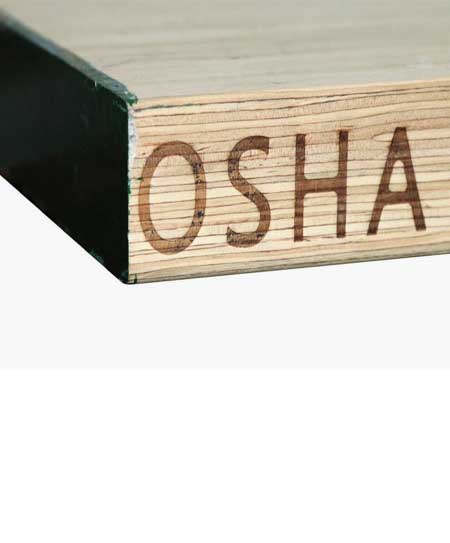

Laminated Veneer Lumber is a type of engineered wood product commonly used in construction for various applications, including beams, headers, and framing. It is made by bonding together multiple layers of thin wood veneers with adhesives under high heat and pressure.

It offers several advantages over traditional lumber, such as higher strength-to-weight ratio, resistance to warping and twisting, and dimensional stability. These properties make LVL a popular choice for structural applications where strength and reliability are essential. Using LVL boards for scaffolding can offer benefits such as uniformity in size and strength, reducing the risk of accidents

LVL OSHA BOARDS

LAMINATED BOARDS

Laminated boards is a broad term that can refer to various types of engineered wood products made by bonding together multiple layers of wood veneers or other materials with adhesives under heat and pressure. These boards are commonly used in construction, furniture making, cabinetry, and other applications where strength, stability, and versatility are required.

Laminated boards provide a versatile and reliable solution for a wide range of construction and woodworking projects, offering strength, stability, and durability while also being customizable to meet specific requirements and design preferences.

Wood-Plastic Composite panels are a type of engineered wood product made from a combination of wood fibers or flour and thermoplastics (such as polyethylene, polypropylene, or PVC) along with additives and stabilizers. These panels are used in various interior and exterior applications, including wall cladding, decking, fencing, and furniture.

WPC panels are a versatile and environmentally friendly alternative to traditional wood or plastic products, offering durability, low maintenance, and aesthetic appeal for a variety of indoor and outdoor applications.

WPC PANELS

BLOCK BOARDS

Blockboards are a type of engineered wood product that consists of a core made from wooden blocks or strips sandwiched between two layers of plywood or veneer. The core of a blockboard typically comprises strips or blocks of softwood or hardwood, which are glued together edge to edge.

The outer layers of a blockboard are made from veneers or plywood sheets, which are glued to the core using adhesives under pressure. These boards are widely used in construction, furniture making, and interior applications where strength, stability, and versatility are essential.